Version of the Brass Compression Limiter line was designed with a thick. Dodge Applications Engineers are available and ready to assist you in the.

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

Anti-Creep Spacers Compression Limiters.

. Brass Stainless Steel Aluminium. Solid Tube Compression Limiters. Included are the specifications for their standard split seam molded-in and solid wall designs as well as their brand new oval series.

These inserts can be installed with heat or ultrasonics or they can be pressed in place. SPIROL USA - Global Headquarters. Below or download the Compression Limiters Design Guide.

SI Brand Compression Limiters. Design guidelines for Compression Limiters to avoid the risk of exceeding the elastic limit of the plastic component. Compression Limiters are plain hole metal inserts designed for use in plastic mould components.

Hole Design Although the split seam Compression Limiters have a broken edge. Design Considerations of Compression Limiters Distilled Spirits manufacturing Fastener Grade and Type Being Used Installation Method Insert Mold or Post Mold Environment of Intended Use Estimated Annual UsageQuantity Required Shape Needed Round Obround Oblong Square etc. SPIROL Engineers will review your application requirements and work with your design team to recommend the best solution at the lowest total assembly cost.

Commonly compression limiters are installed using a simple cold press assembly method. The Compression Limiter will absorb additional clamping loads without further significant compression or increased stress in the plastic material. A Compression Limiter for their assembly.

A gas spring is a type of spring that unlike a typical mechanical spring that relies on elastic deformation uses compressed gas. 1 Design Guide Threaded Inserts For Plastics a ten point guide. Danielson CT SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assembliesIncluded are the specifications for their standard split seam molded-in and solid wall designs as well as their brand new oval series.

It provides bolt clearance while the wall of the compression limiter withstands the compressive force induced during the assembly of the mating screw or bolt. Contact Us for More Information. To customize a compression limiter or send us your design and specifications request a custom quote.

They are designed with various knurl configurations and undercuts in order to meet the strength requirements of the specific application. Request a Quote Compression Limiters Manufacturing. Thereafter the Compression Limiter and plastic will compress at the same although greatly reduced rate.

Compression limiters are made to meet your individual specifications. 1 Prepare holes with a taper of 1. Download the latest SPIROL Compression Limiters Design Guide for help in selecting the best Compression Limiter for your assembly.

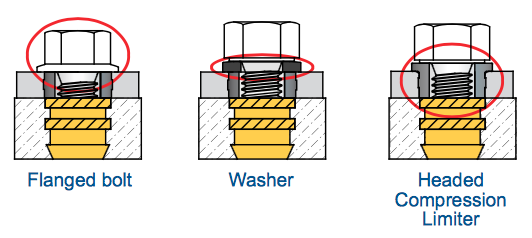

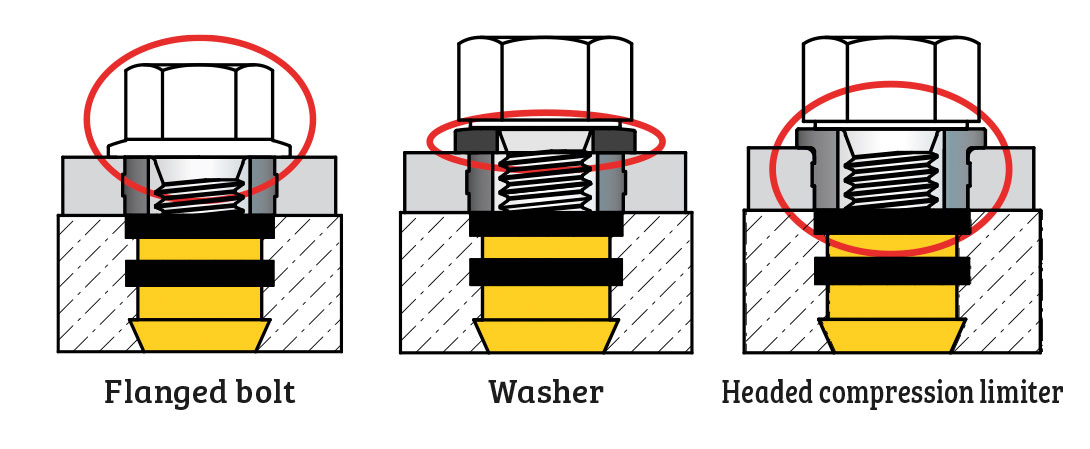

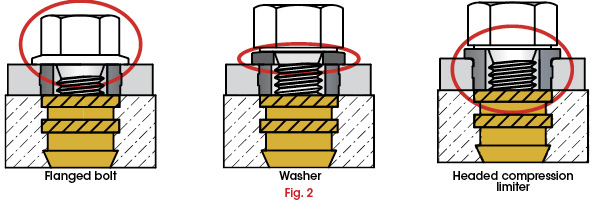

The head of the bolt or washer if one is used comes into contact with the Compression Limiter. It Is Highly Efficient in Overload Protection. Applications Engineering Support.

The Limiters can be pressed in or installed with either heat or ultrasonics. Since that time SPIROL has worked with hundreds of companies who required. Solid compression limiters provide a strong and reliable defence against the stresses caused by fastener torque.

The primary function of a Compression Limiter is to provide and maintain joint integrity. Wall to prevent the plastic from cracking as a result of the expected clamp. Hear What Our Customers Say.

They are designed to minimize any. Since our opening in 2013. SPIROL Compression Limiter Design Guide SPIROL Corporate Brochure Contact the supplier.

Guidance and advice for those involved in the design of plastic products requiring threaded inserts. 3 Compression limiters with various surface geometries can also be developed. Compression limiters are non-threaded bushings made of various materials.

2 Tappex 2019 Brochure. Ad Be Prepared For Your Next Job With the Most Reliable Fittings Available. A standard joint needs a compression limiter of some form to control foam compression level.

Global manufacturer of innovative fastening solutions that improve product quality simplify the assembly process and reduce manufacturing costsEngineering assistance available. SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies. Our compression limiters are produced using brass aluminum stainless steel or steel and can be produced with or without a variety of plating finishing options as well as optional quality.

The compression limiter strengthens the plastic and withstands the compressive force that is applied when a mating screw is tightened. Compression limiters are a type of insert or bushing designed to maintain joint integrity of a plastic assembly when tightening bolts or screws. Compression Limiters by SPIROL Piston guide bushing 12.

They protect plastic parts from damage due to compression by limiting the force that gets applied to the plastic by the assembly fasteners. Compression Limiters Dodge non-threaded bushings expand the Dodge offering and are custom designed for your specific application. Compression limiters are non-threaded inserts that are commonly used in applications where a compressive load is applied to a plastic assembly.

The integrity of the plastic is. Ad Protect Your Components from Damage Using Our Tolerance Ring. Load generated by the tightening of the bolts.

Compression limiters are designed for applications where the. 2 The plastic walls must have a thickness that is at least 50 of the diameter of the screw to be used. Headed Compression Limiters are only available as solid components because of the tolerances required for proper Compression Limiter operation.

Installation of Compression Limiters can be done through various technique using heat ultrasonic mold-in or press-in. Tongue and groove Upper tongue increases contact face with foam. Robafoam Design Guide Robafoam Ltd is a specialist foam sealing company based in Leamington Spa.

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

Expanded Compression Limiters Design Guide

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fastener Fixing Magazine

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly 2015 11 04 Assembly Magazine Assembly

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fluid Power Journal

0 comments

Post a Comment